Wire rope, you may think

what this is and why this blog is important? But wire rope plays a very vital

role in various industries for various applications.

Let us understand the concept and maintenance of wire rope

Wire rope is basically made of metal wires.

Let us consider how wire ropes are constructed, wire rope will have four main components

1. Core

2. Strand

3. Wire

4. Wire rope

Metal wires are twisted in the form of helix and will form one strand, similarly

when these strands will be twisted over center strand then we will

secure wire rope. The center strand will be core around which strands

will be twisted to form the desired wire rope.

Wire rope

Wire rope construction

Wire rope specifications

During purchase order

for wire rope, we must have to produce the desired specifications as mentioned

below.

- Dimension: length and diameter of wire rope.

- Construction: Number of wires in one strand and numbers of strands in wire rope.

- Type of Core: Fiber CF or steel wire CWR.

- Type of lay: Lang lay and regular lay.

- Direction of lay: Right hand or Left hand.

- Tensile designation 1570, 1960.

- Area of applications.

- Finishing: Galvanized or ungalvanized.

Protection of wire rope and routine maintenance

Wire ropes are generally

used in crane for example harbor crane, mobile crane, electric overhead

travelling crane. Normally life of wire rope depends on the environment and

area of applications.

Let us consider one example, wire rope will have less life span if wire rope will be used in steel sector EOT crane or in Port sector as compared to wire rope which is used in simple mobile crane .

Let us consider one example, wire rope will have less life span if wire rope will be used in steel sector EOT crane or in Port sector as compared to wire rope which is used in simple mobile crane .

In order to increase the

life of wire rope we must have to protect the wire rope against oxidation,

hence galvanized wire ropes are preferred normally. In our routine maintenance

we will have to take care of sufficient lubrication of wire rope in order to

avoid the friction.

Reason of failure of wire rope

We have carried out lot

of research in steel sector and port sector and finally we have decided some

major reasons, those are as mentioned below, for failure of wire rope.

Heat, corrosion, fatigue

and miss-application of equipment

Deterioration of wire

rope is normally depends on various factors depending on

various conditions of applications of wire rope

Let us consider one

example; corrosion is the main factor of deterioration of wire ropes

in port sectors and it is because of moisture.

Let us consider the other

factor that affects the life as we have observed following points

- Wear

- Corrosion

- Kinks

- Fatigue

- Application of wire rope

- Mechanical abuse

- Non availability of lubricant

- Overloading

Safe working load

Safe working load =

Nominal breaking strength/Load

Inspection of wire rope

I have observed in

our industrial experience as well as learning from steel sector and port sector, I have concluded that we must check wire rope once thoroughly in 24 hours as

wire rope inspection is very important for maintaining safe working culture in

any industry

The inspection of

wire rope in regards with maintenance as well as for replacement, we must

follow the American National Standard B30 Codes.

We used to inspect wire

rope and we used to write detailed report of wire rope for making a history

record for future reference.

Let us consider the factors that we used to inspect in wire rope as mentioned below

- Wire rope nominal diameter reduction; it must be less than 10 % of initial nominal diameter of wire rope.

- Presence of wire broken in wire rope: we have made one replacement criteria of wire rope on the basis of numbers of broken wires and these criteria are as mentioned below. If four wires are broken in one strand — we must have to plan replace the wire rope. If 7 to 8 wires are broken in one lay length –we must have to plan replace the wire rope.

- Outside wear rate condition.

- If there is any proof of damage due to heat

- If there is any twisting in wire rope?

- Fatigue, broken wires and corroded at one end

- If there is any proof of crushing or cutting

- If we have observed any contact with one energized electrical conductor

But we must note that

there is not any thumb rule for replacement of wire rope but also it depends of

wire rope inspector experience and qualification.

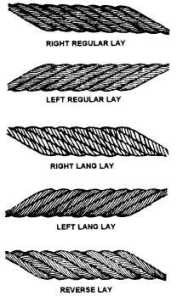

Wire rope lay

Wire rope lay is

basically defined as the direction of twisting of metal wires in

strand and the direction of twisting of strand in the wire rope.

In some cases, the

direction of twisting of metal wires in strand and the direction of

twisting of strand in the wire rope will be in same direction.

In some other cases ,

depending on the application of the wire rope, the

direction of twisting of metal wires in strand and the direction of

twisting of strand in the wire rope will be in opposite

direction.

For better understanding let us see some pictures where we will see various wire rope lay

We will also discuss the

various types of cranes in our next post

No comments:

Post a Comment