Stress in Thin Spherical Shell – Engineering Made Easy

In the field of engineering mechanics and structural analysis, understanding the stress distribution in thin-walled…

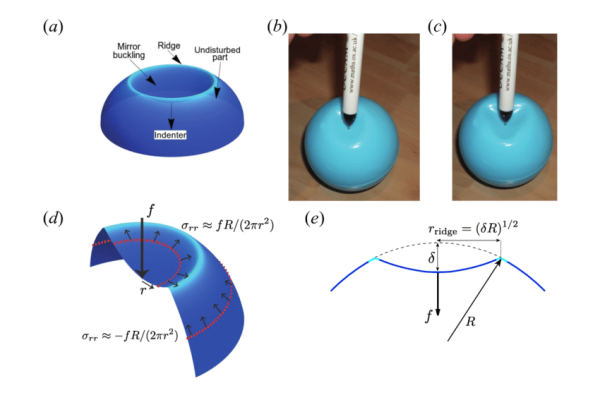

In the field of engineering mechanics and structural analysis, understanding the stress distribution in thin-walled pressure vessels is fundamental to the safe and efficient design of numerous engineering components. Among the various geometries of pressure vessels, spherical shells represent one of the most efficient configurations for containing internal pressure due to their uniform stress distribution…

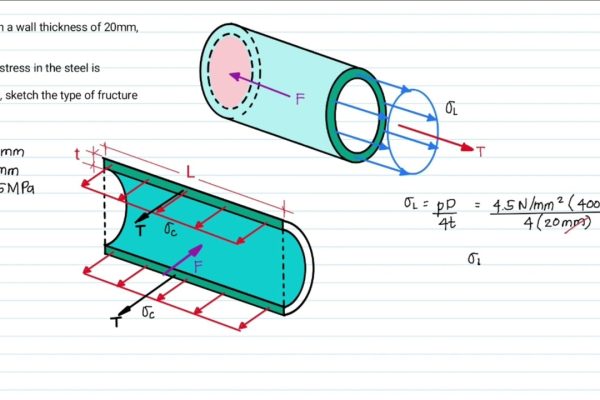

In the field of mechanical and structural engineering, understanding the stress distribution in thin-walled pressure vessels is fundamental to ensuring the safe and efficient design of numerous engineering components. Among the various geometries of pressure vessels, cylindrical shells are among the most commonly encountered due to their practical advantages in manufacturing, space utilization, and connection…

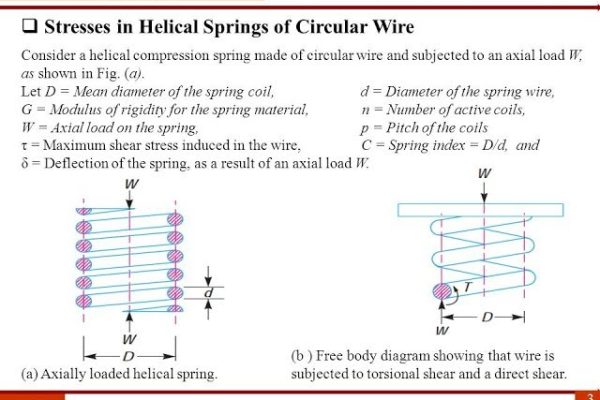

In the field of mechanical engineering, helical springs are among the most commonly used mechanical elements for storing and releasing energy, providing force, and absorbing shocks. Understanding the behavior of these springs under load, particularly their deflection and stiffness characteristics, is fundamental to their proper design and application in various engineering systems. Closed coil helical…

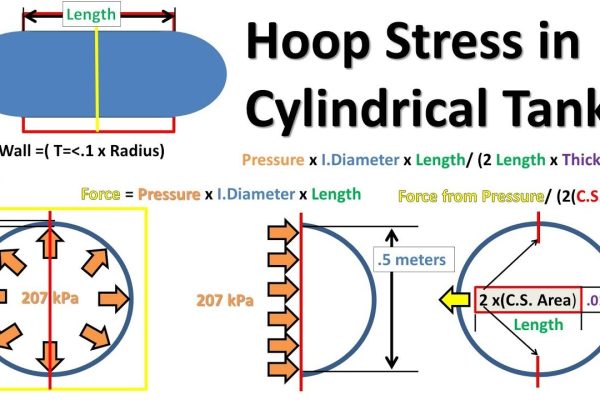

In the field of mechanical and structural engineering, understanding the stress distribution in thin-walled pressure vessels is fundamental to ensuring the safe and efficient design of numerous engineering components. Among cylindrical pressure vessels, hoop stress (also known as circumferential stress) represents the most critical stress component due to its higher magnitude compared to longitudinal stress….

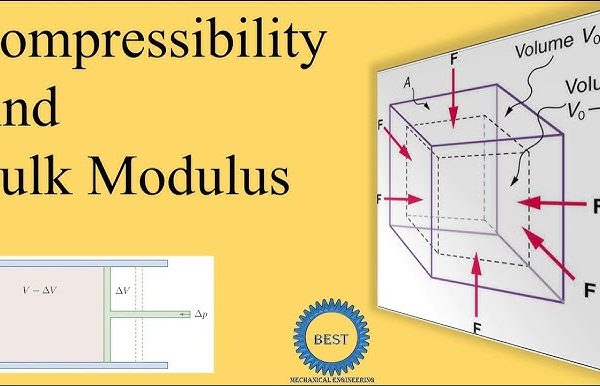

In the study of fluid mechanics, understanding the compressibility of fluids and the associated bulk modulus is fundamental to analyzing how substances respond to pressure changes. These properties are crucial for engineers working with hydraulic systems, pipeline design, water hammer analysis, and numerous other applications where fluid behavior under pressure is critical. While gases are…

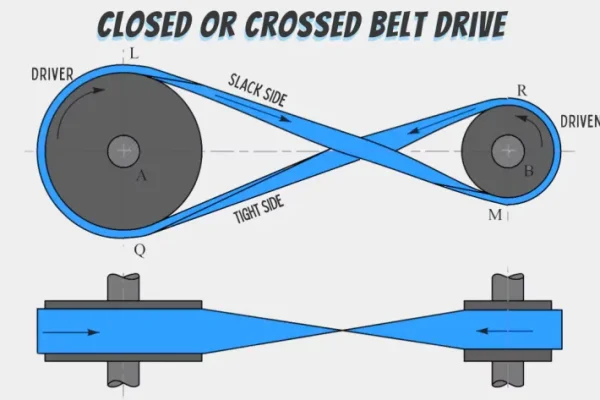

In the field of mechanical engineering and maintenance, belt drives represent one of the most widely used and versatile methods for transmitting power between rotating shafts. These flexible power transmission systems have been fundamental to industrial machinery since the early days of mechanization and continue to play a crucial role in modern manufacturing, transportation, and…

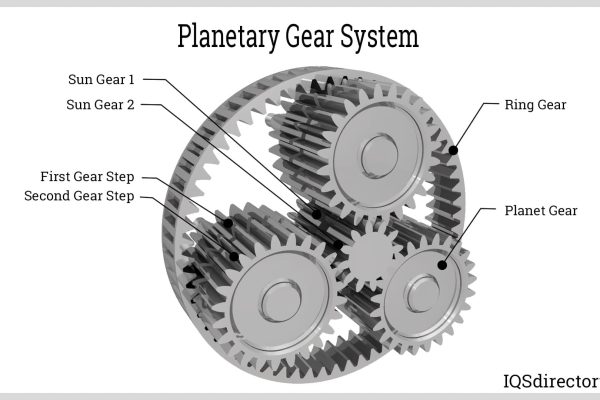

In the field of mechanical engineering and maintenance, planetary gear systems represent one of the most sophisticated and versatile mechanisms for power transmission. Also known as epicyclic gear trains, these complex assemblies offer unique advantages in terms of power density, compactness, and versatility that make them indispensable in numerous modern applications. Planetary gears are characterized…

In the field of mechanical engineering and maintenance, the proper installation of rolling element bearings is critical to ensuring optimal performance, longevity, and reliability of rotating machinery. One of the most significant challenges in bearing installation is achieving the proper interference fit between the bearing inner ring and the shaft, particularly when tight tolerances are…

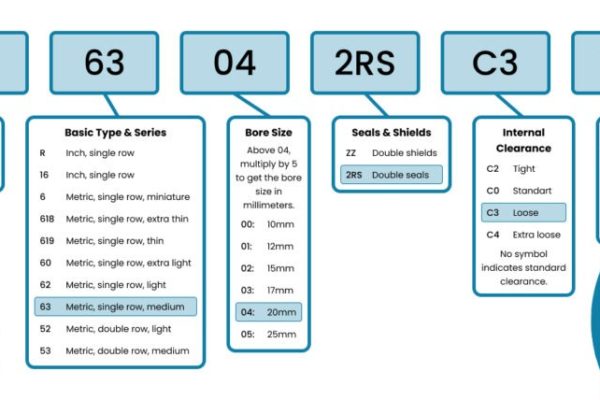

In the field of mechanical engineering and maintenance, rolling element bearings are among the most critical components in machinery and equipment. These precision components enable smooth rotational motion while supporting radial and axial loads in countless applications, from automotive wheel hubs to industrial turbines. Understanding bearing numbers is essential for engineers, maintenance personnel, and procurement…

In the field of mechanical engineering and maintenance, gear systems are fundamental components for power transmission in countless machines and mechanisms. Among the various types of gears used in industrial applications, helical gears and spur gears represent two of the most common and important configurations for transmitting power between parallel shafts. Understanding the differences between…